Almond Board Of California Validation

In an attempt to identify.

Almond board of california validation. Prepare inoculum days 5 6. Almond board of california process validation guidelines at bottom of page codex codex alimentarius commission. Validation is a rigorous process in which testing is conducted to demonstrate the ability to destroy microorganisms on almonds. Inoculate almonds assess initial inoculation levels and determine heat resistance days 7 14.

Guidelines for validation of dry roasting processes overview the almond board of california abc working with researchers from universities and commercial laboratories initiated several projects addressing lethality of dry heat processes. Almond board of california approved process authorities january 21 2020 the almond board of california abc has approved the following process authorities pas for use by handlers custom processors and direct verifiable dv users for the purpose of pasteurization process and equipment validation. Begin validation trials with inoculated almonds. The site you are transferring to is not hosted by the almond board of california but rather by a valued 3rd party information source.

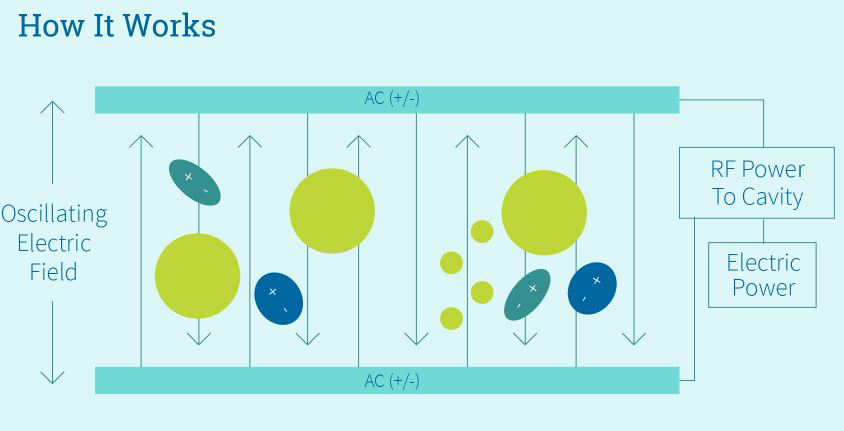

University of california parlier almond board objectives. Seasonal monitoring of peach twig borer anarsia lineatella and san jose scale quadraspidiotus perniciosus was conducted with pheromone traps for additional validation of phenology models for these 2 species. Guidelines for process validation using enterococcus faecium nrrl b 2354 the almond board of california abc funded research projects with silliker research center michigan state university the national food laboratory and deibel laboratories inc. There are several types of validated processes that effectively eliminate potential contamination in almonds without diminishing the product s quality nutritional value or sensory qualities.

Validation number provided upon request. Joint fao who food standards program fao rome. The information reported in this. This link has been provided solely as a convenience to you but the almond board of california cannot assume responsibility for the accuracy quality safety or nature of the content throughout the linked site.

Validation and the processes. Guidelines for the validation of food safety control measures cac gl 69 2008. All processes used to treat almonds must be validated by an abc approved process authority and approved by abc s technical expert review panel. Validation of ppo treatment chambers and operations a process authority should carefully study all of the supporting documents mentioned above before proceeding to validate any chambers or processes.

Almond board of california. Use inoculated almonds within. Ccp s facility is operated and monitored by hazard analysis and critical control point program haccp our blanching line is validated to operate within the established sop parameters established by the almond board of california.