Alum Polymer Water Treatment

For raw water applications polymer products help to eliminate the need for ph adjustment decrease the load on demineralizers increase filter throughout and significantly reduce sludge volume.

Alum polymer water treatment. Alumer is usalco s blend of iron free aluminum sulfate alum with a polymer. Alum or aluminum sulfate. Once the repulsive charges have been neutralized since opposite charges attract. Accepta s extensive range of advanced technology polymers and polymeric treatment chemicals offer superior performance and have been developed for use in a wide range of demanding commercial industrial and municipal applications involving the treatment of process waters wastewater and effluent treatment.

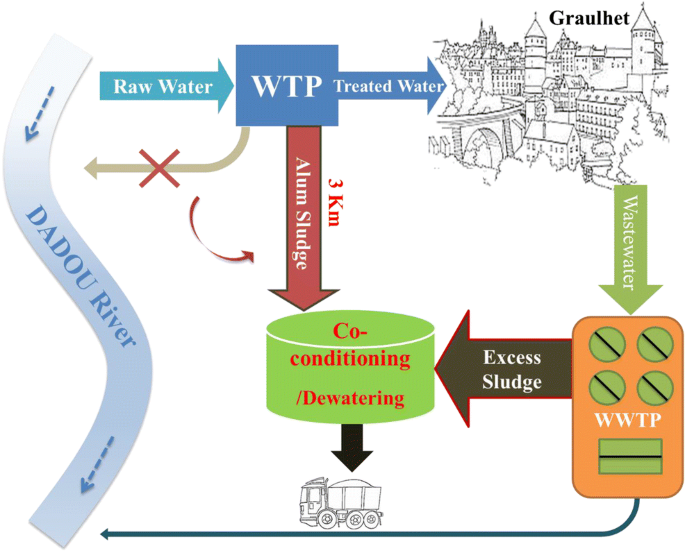

Usalco s extensive line of aluminum based chemicals for wastewater treatment offer numerous benefits which include. Alum and ferric chloride are two widely used commodity chemical coagulants that have been around for a long time. Effective coagulation and solids settling. Polymer chemistry can address many important challenges in industrial applications but the process of combining producing and deploying polymer products is very complex expensive and time consuming.

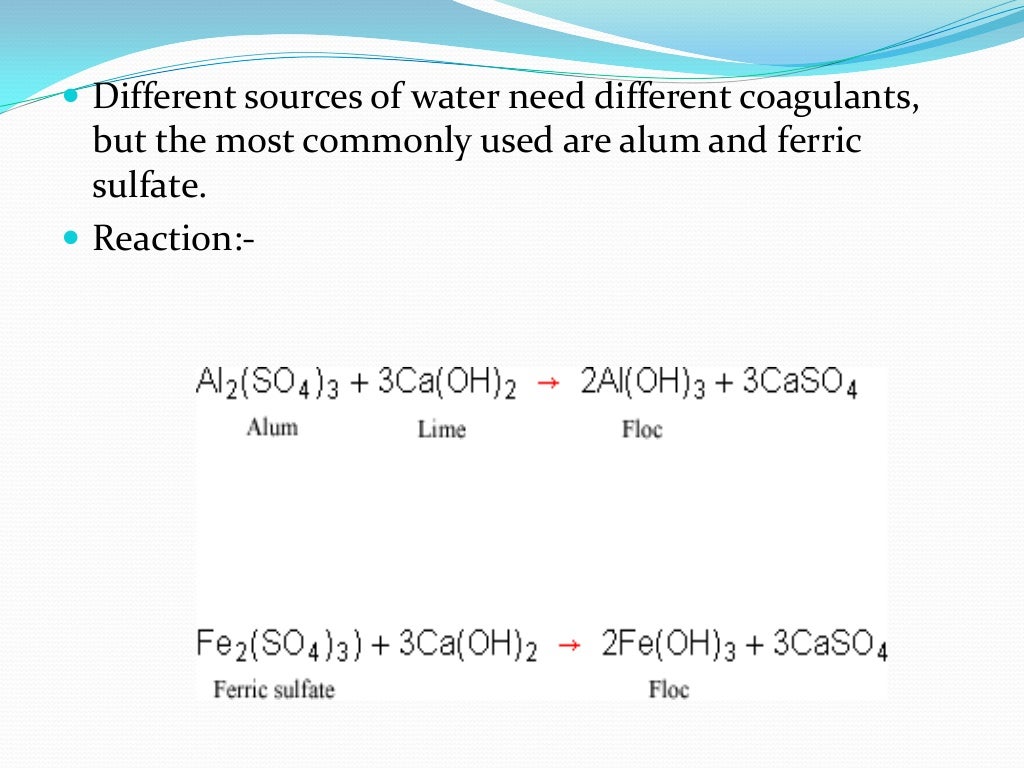

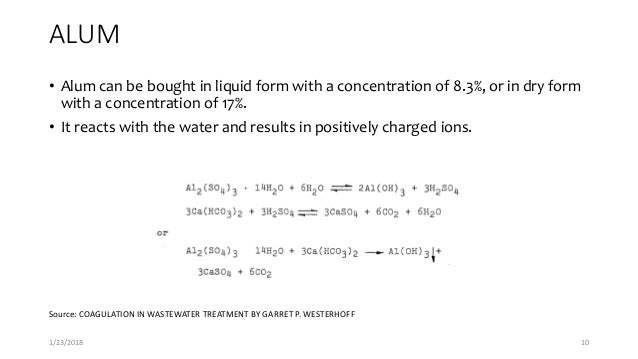

Primary coagulants neutralize the electrical charges of particles in the water which causes the particles to clump together. It is used for water treatment facilities including drinking water and industrial make up water. To induce coagulation a coagulant typically a metallic salt with the opposite charge is added to the water to overcome the repulsive charge and destabilize the suspension. In wastewater treatment these clarification aids help with the removal of other contaminants such as oil phosphate and heavy metals.

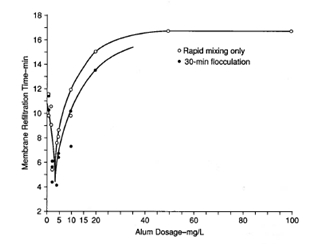

Chemically coagulant water treatment chemicals are either metallic salts such as alum or polymers. As every water treater knows coagulants are used in the first step of water treatment. Usalco s proven ability to blend iron free low contaminant alum with a variety of highly effective polyelectrolytes provides a unique synergy never found in previous alum polymer blends. Many water utilities are committed to consistently producing treated water turbidities of less than 0 1 ntu to guard.

In modern water treatment coagulation and flocculation are still essential components of the overall suite of treatment processes understandably because since 1989 the regulatory limit in the us for treated water turbidity has progressively reduced from 1 0 ntu in 1989 to 0 3 ntu today. They destabilize the water so micro flocks can begin to form. For example the colloidal particles are negatively charged and alum is added as a coagulant to create positively charged ions. Reducing polymer usage saves wastewater treatment plants precious time money and labor.

Coagulant water treatment chemicals come in two main types primary water treatment coagulants and coagulant aids. Accepta s comprehensive range of polymers has been. The use of polymer products is needed in wastewater treatment when the traditional iron based ferric and aluminum based compounds are used to deal with the core problem of phosphorus reduction. By 1757 alum was being used for coagulation in municipal water treatment in england.

Products often purchased by wastewater treatment plants include.